Petroleum Equipment Manufacturer

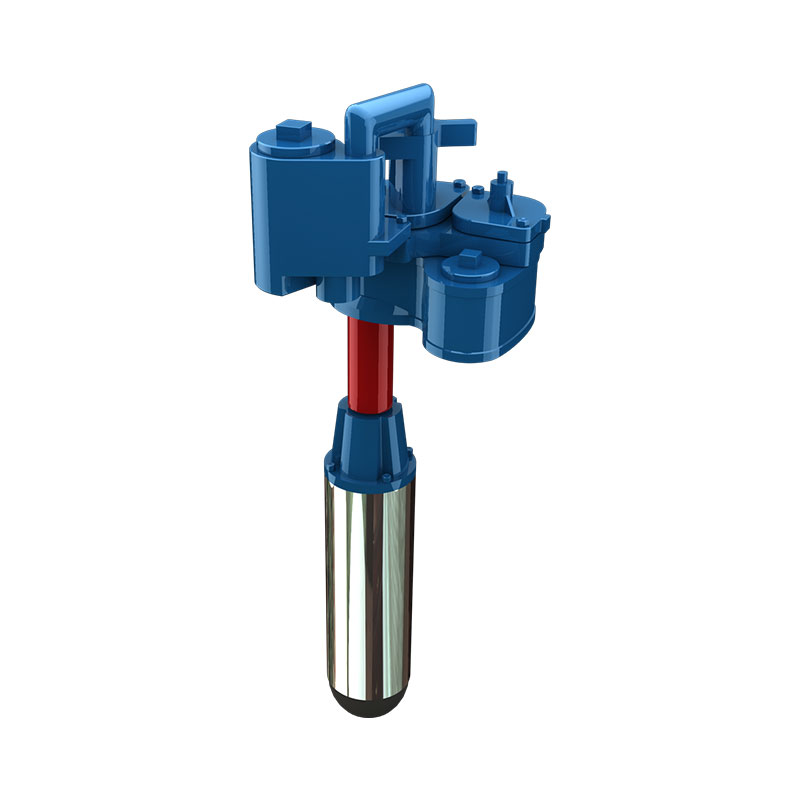

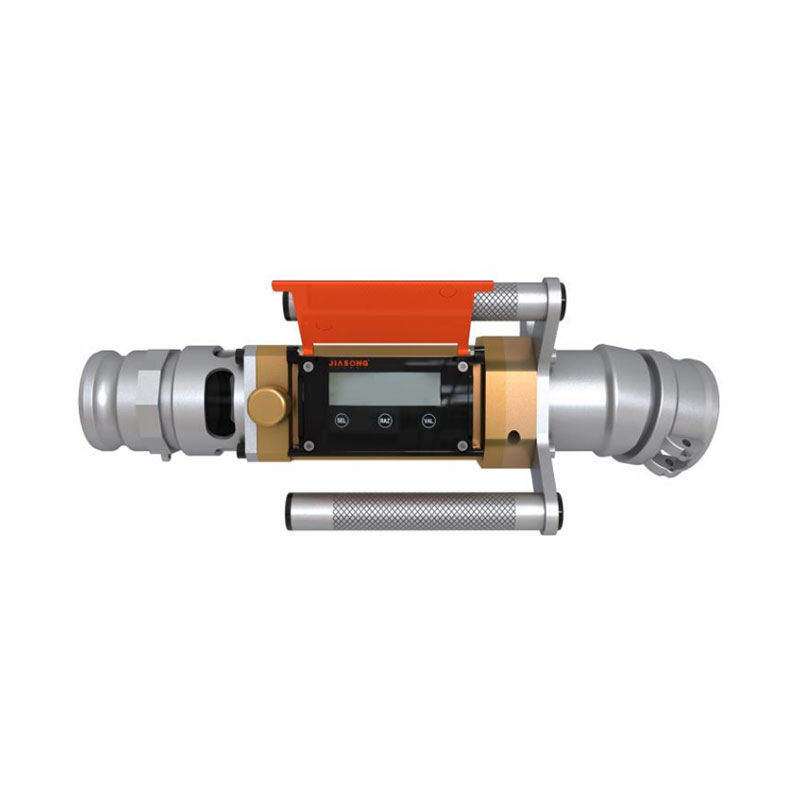

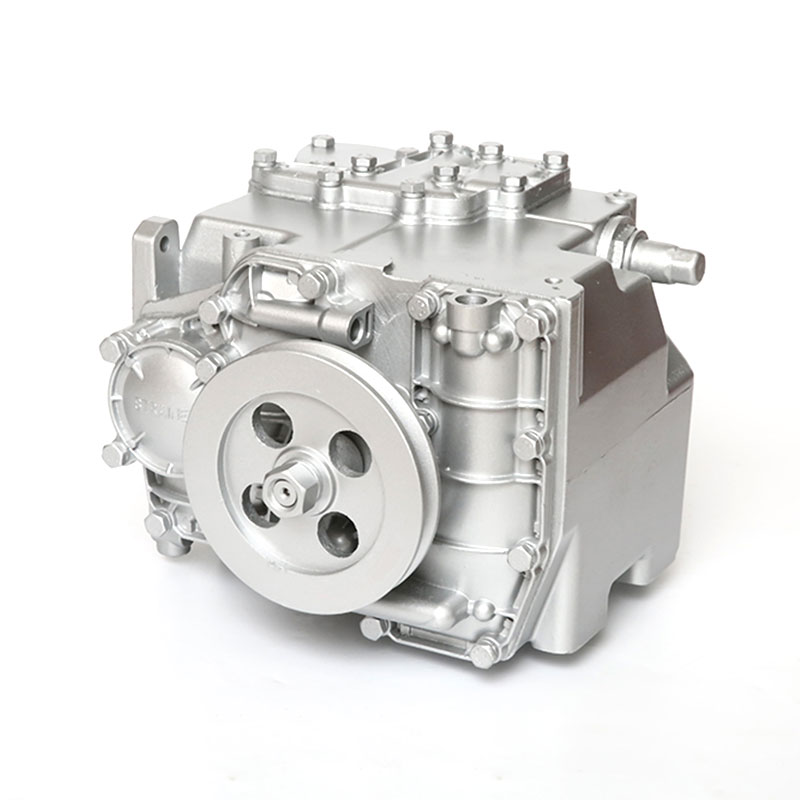

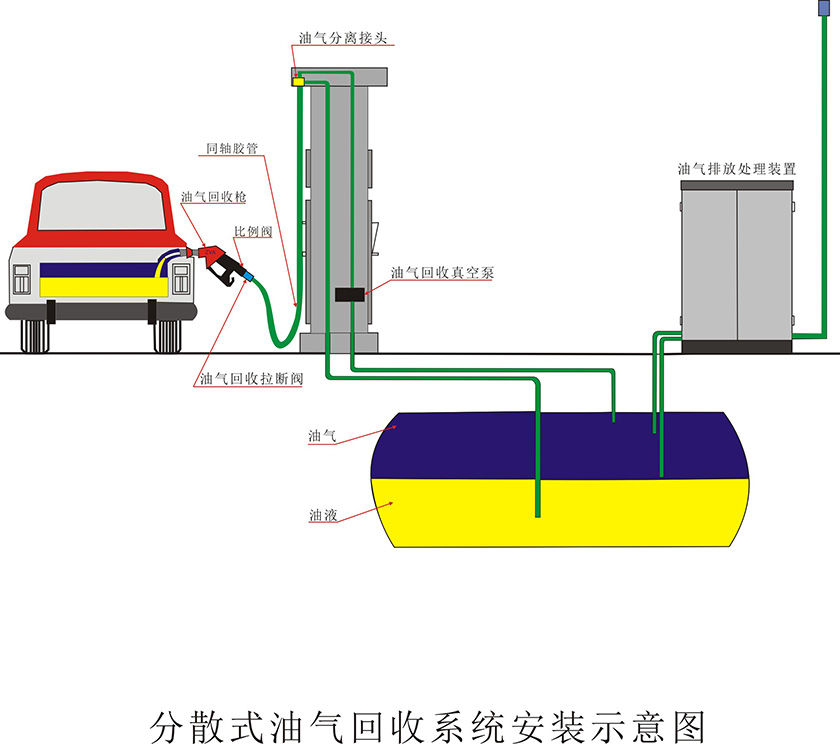

We are a petroleum equipment manufacturer, specialized in researching, producing, selling and servicing of Fuel Dispenser, Combination Pump, Gear Pump, Submersible Pump, Flowmeter, etc., and also the equipments of tank, refinery and oil tanker.

About Company

Jiasong gets involved in petroleum equipments and launches new products continuously.

200

+

Working Member

Our Mission & Value

Provide first-class domestic equipment and accessories to China's petrochemical industry.

Company

Qualification

Since establishment, Jiasong attaches great importance to brand and capacity building. In recent years, the company has made a breakthrough in market access and qualification certification. The main qualification certificates obtained by our company recently include but are not limited to :